Things to Do | Visit Chiba | Latest update:2024/03/24

The art of manufacturing glass is an old one, a process which has been refined for thousands of years. With technology becoming increasingly advanced, some glass makers have adopted new techniques. At Suki Glass Studio however, the glass making process seemed simple and graceful, but certainly not easy or effortless. I don’t know about you, but I’ve never just stopped to appreciate the art of glassblowing and I’ve always taken glassware for granted. Every glass, every vase, every bottle was just something I used and discarded once I was finished with it. However, after an afternoon at Suki Glass Studio, my perspective totally changed.

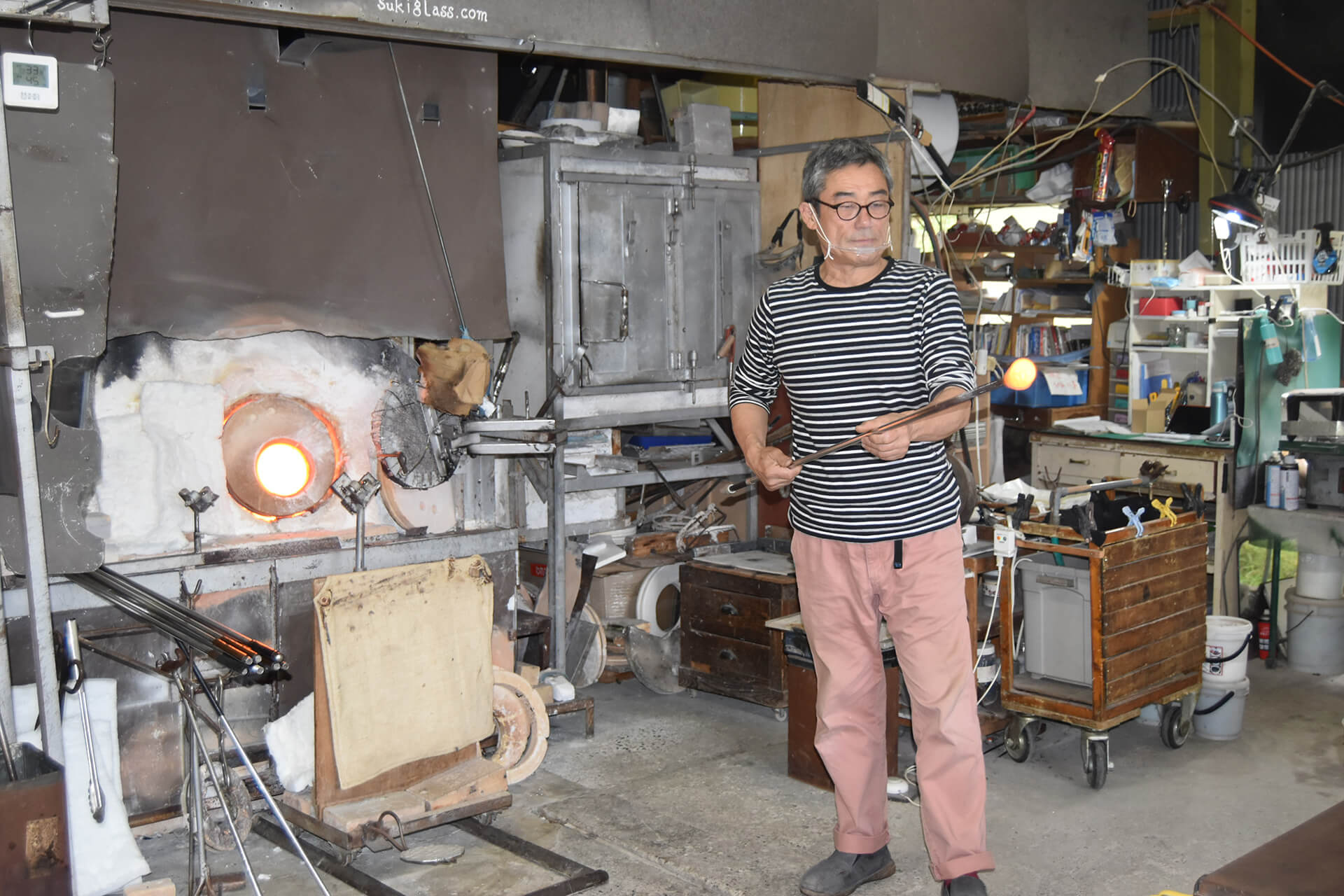

Mr. Suzuki, the instructor, took me through the process of making a glass vase. He made it sound easy while explaining it, but the actual process was very nuanced and detailed. In order to make clear glass, the right set of raw materials is required. These ingredients are mixed in the right proportion, and the entire batch is flown into a furnace that’s been heated to anywhere from 800 to 1000 degrees Celsius. In order to impart color to the glass, certain metal oxides are also mixed in the batch.

That’s where I began my experience. I started by first selecting which shape and color of glass that I wanted to make. There are over 50 colors and a wide range of shapes and patterns you can choose from! Bowls, goblets, cups, wineglasses, vases, any shape that you can think of is on the menu. It is even possible to create pieces with a combination of colors or layered version with streaks, motifs, and other colorful designs. With the seemingly endless variety of colors, it took me a while to choose which one I wanted to go with, but I kept it simple and opted for modest goblet design in a shade of blue.

The process of actually making the glass goblet began by heating the glass up to between 800 and 1000 degrees Celsius. The heating process takes a bit of time, but getting the temperature right and the initial heating are crucial steps. Once the glass was heated properly and melted into a workable red-hot glob, we transitioned into the molding part of the process. I began molding the goblet by continuously rolling and occasionally blowing air into the glass through a long and hollow steel pipe.

The rolling speed and angle at which you hold the molten glass needs to be just right. If rolled too fast or too slow the desired shape of the glass cannot be achieved. Mr. Suzuki made sure that I kept my rolling at just the right speed while coaching me on when to blow air into the glass. It was impossible for me to know when to adjust my speed and blow air, but after many years of practice Mr. Suzuki could simply look at my project and tell me exactly what to do.

There are a couple of things that you need to keep in mind while going through the process. First, if the temperature of the glass dips below 400 degrees Celsius, it will break. Second, when you’re rolling the glass, if you hold it in one position for too long, it will fall off of the rod.

After a long back and forth which consisted of re-heating, rolling and occasionally blowing air into the glass, my goblet began to take shape and look like something that I could be proud of. Upon completion, the glass was stored in a kiln for cooling, where it took about 15 hours for it to gradually cool down.

Mr. Suzuki’s studio is surrounded by beautiful, natural scenery and adorned with a variety of colorful glassware in all different shapes and sizes.

This is a fun activity for all ages! Stop by Mr. Suzuki’s studio if you have an opportunity to visit Kamogawa City in Chiba!

410 Kamikobara, Kamogawa City

(15 minutes by car from JR Awa-Kamogawa Station.)

+81-47-097-1443